Monorail transport systems

SMART Logistic Technology is a method of allowing the shuttles to operate the rail system of a Montrac transport system independently of a master control.

The centrepiece of intelligent automation

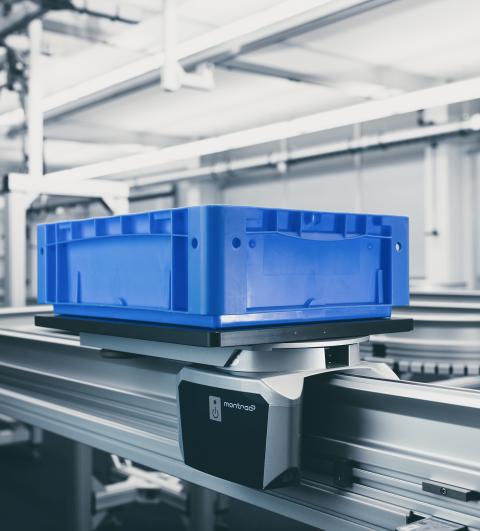

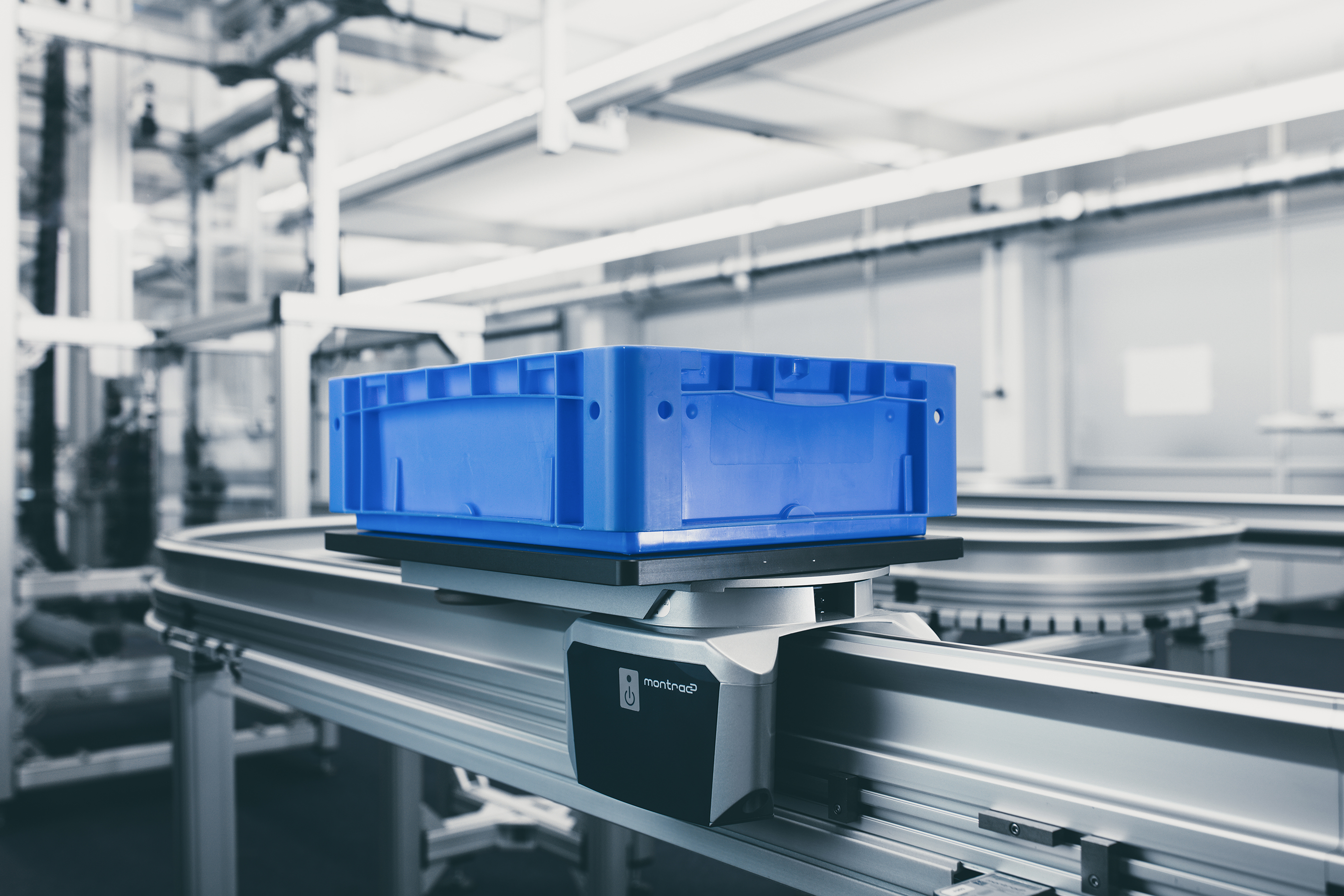

Core components of the montrac® system, montrac® shuttles are intelligent single or twin-axle conveyors equipped with an on-board power supply. Moving self-centred on the monorail, the shuttles are equipped with state-of-the-art sensors that prevent potential collisions with obstacles or other shuttles.

Each shuttle is powered by a maintenance-free, low-voltage motor located in the axle. Cams on the T-grooves along the track specify shuttle speed and stopping positions. Speed parameters can be pre-configured to optimally meet your individual requirements.

MONTRAC configurator

The Montrac configurator is a very easy-to-use and free software within which you can create individual transport system layouts with a few mouse clicks. In the configurator, all standard components of the Montrac system are stored in a product library. With drag and drop the desired components are positioned in the configuration window. The software autonomously detects the connection points. It is also possible to import the 2D drawings of the surroundings.

The Montrac configurator can be downloaded for free from the www.montratec.com website.

Shuttle S015 & X030

The standard shuttle for many transport operations offering a maximum speed of 55 m/min and loads of up to 30 kg.

Shuttle S015 & X030

Shuttle S014CR & X021CR

The cleanroom shuttle specifically for cleanroom applications. Rubberised drive and support rollers optimised to minimise friction with a minimal point of contact on the monorail, in tandem with contactless rather than mechanical braking, result in extremely low particle emissions. Maximum speed 55 m/min, max. load 30 kg.

Shuttle S014CR & X021CR

Shuttle X050

Next generation transport efficiency. Shuttle variants with payloads up to 50 kg offer the perfect transport solution for any application. Innovative 5-beam sensor modules that are optionally available on the front and rear axles ensure collision free and monitored turning and reversing while also allowing wide workpiece carriers to be monitored.

Shuttle X050

Shuttle W040 & W070

Technical advancement of Generation X. The two shuttle variants with a payload of up to 40 kg (W040) and up to 70 kg (W070) transport heavy workpieces safely via the space-saving monorail. Possible collisions are prevented by innovative sensor modules. The W070 also offers optional sensor-monitored reversing.