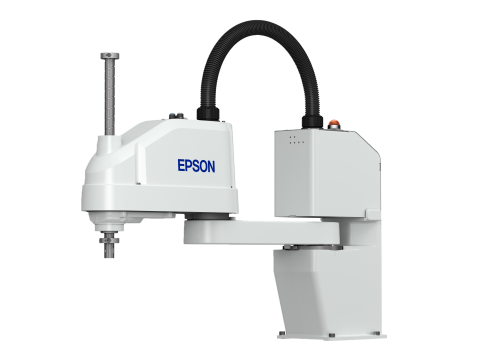

These SCARA robots require no complicated setup and maintenance such as a single-shaft robot. Thanks to the low operating costs they can easily be used for simple automation tasks. Manufacturers who automate tasks by combining multiple low-cost single-axis robots will find that they can replace these with T3 robots. Doing so will enable them to reduce or eliminate troublesome single-axis robot maintenance work and save money over the long run. Deploying T3 robots will enable factory owners to free up space that was taken up by a large number of robots and use their floor space more efficiently and productively.

A new concept of motors eliminates the need for back-up batteries for the position of the robot when the power supply is switched off, making downtimes for battery changes a thing of the past.

Benefits of the EPSON T-series at a glance

- Flexible due to 4 axes: greater variation in movement

- Intelligent thanks to the integrated, powerful robot controller with system connection

- Efficient operation and maintenance thanks to simple cabling

- Energy-saving due to lower power consumption

- Space-saving – compact unit with a very small footprint – no separate space required for the controller

- Sustainable thanks to a position sensor system without batteries

- Available from stock

- As of EUR 7,500 ex 21% VAT